| Single-component valves | Two-component valves | Spray | Without contact | ||||

|---|---|---|---|---|---|---|---|

| Volumetric | Standard | Volumetric | Volumetric | Standard | Marco | ||

| Deposit models | Point | ✓ | ✓ | ✓ | × | × | ✓ |

| Cord | ✓ | ✓ | ✓ | × | × | ✓ | |

| Potting / Coating | ✓ | ✓ | ✓ | × | × | × | |

| Varnishing / Tropicalization | × | × | × | × | × | × | |

| Types of adhesive | UV | ✓ | ✓ | × | × | × | ✓ |

| Methacrylate | × | × | ✓ | × | × | × | |

| Polyurethane | × | × | ✓ | × | × | × | |

| Epoxy | ✓ | × | ✓ | × | × | ✓ | |

| Cyanocrylate | × | ✓ | × | × | × | × | |

| Hybrid | × | × | ✓ | × | × | × | |

| Silicone | ✓ | ✓ | × | × | × | × | |

| Grease / Ink / Oil / Other | ✓ | ✓ | × | × | × | ✓ | |

| Reference | KEOL 530 | KEOL-303 | KEOL-300 T |

|---|---|---|---|

| Weight | - g | 240 g | 225 g |

| Dimensions | L 115mm - Ø 28mm | L 115mm - Ø 29mm | L 150mm - Ø 30mm |

| Valve type | Needle valve | Diaphragm valve | Diaphragm valve |

| Repeatability | ±2,5 % | ±2,5 % | ±5 % |

| Control box | KEOL-VC 1000 | KEOL-VC 1000 | KEOL-VC 1000 |

| Technical datasheet (copie) |

Boîtier de contrôle KEOL-VC 1000

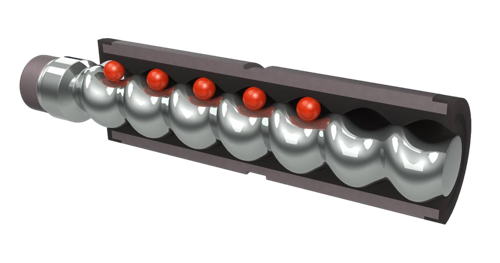

The volumetric dosing pump is designed for precise and repetitive dosing of all kinds of materials: product loaded with particles, high viscosity product, based on one or two components. With the volumetric dispenser, the reproducibility of the dispensing is greater than 99% with a degree of precision of ± 1%. Whatever the external conditions during the dispensing operation, the dosing precision remains constant.

| Reference | KEOL-K 300 | KEOL-K 330 | KEOL-K 450 | KEOL-K 600 | KEOL-K 700 |

|---|---|---|---|---|---|

| Valve type | Volumetric | Volumetric | Volumetric | Volumetric | Volumetric |

| Weight | Env. 380 g | Env. 410 g | Env. 410 g | Env. 750 g | Env. 750 g |

| Volume flow rate | Env. 0,012 ml/rotation | Env. 0,03 ml/rotation | Env. 0,05 ml/rotation | Env. 0,14 ml/rotation | Env. 0,53 ml/rotation |

| Spray precision | ±1 % | ±1 % | ±1 % | ±1 % | ±1 % |

| Control box | KEOL-K 200 Mono | KEOL-K 200 Mono | KEOL-K 200 Mono | KEOL-K 200 Mono | KEOL-K 200 Mono |

| Technical datasheet |

Volumetric metering valves are designed for precision metering and repeatable dispensing of all kinds of materials: product loaded with particles, high viscosity product. With the volumetric doser, the reproducibility of the dispensing is greater than 99% with a degree of precision of ± 1%. Whatever the external conditions during the dispensing operation, the dosing precision remains constant.

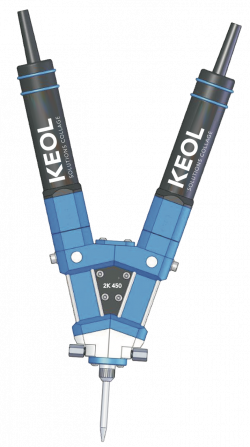

| Reference | KEOL-2K 330 | KEOL-2K 450 | KEOL-2K 600 |

|---|---|---|---|

| Valve type | Volumetric | Volumetric | Volumetric |

| Weight | NS. 1,100 g (without training) | NS. 1,100 g (without training) | NS. 1,600 g (without training) |

| Dosing volume | NS. 0.028 ml / rev per dispenser | NS. 0.05 ml / rev per dispenser | NS. 0.140 ml / U pro dispensed |

| Dosing precision | ±1 % | ±1 % | ±1 % |

| Volume flow rate | 0.1 to 6.6 ml / min (for 1: 1) | 0.2 to 12 ml / min | 0.6 to 32 ml / min |

| Control box | KEOL-2K CONTROL | KEOL-2K CONTROL | KEOL-2K CONTROL |

| Technical datasheet |

Boitiers de contrôle KEOL-2K CONTROL et KEOL-K PLUG&DUO

Spray dosing valves guarantee an application by spraying evenly. Generally used for selective deposits on printed circuit / PCB, can also be used in the context of varnishing or tropicalization to guarantee the protection of sensitive components and avoid savings masks. The spray dosing valves can be used for the precise application of glue, resin, ink, grease and spray oil.

| Reference | KEOL-K SPRAY | KEOL-500 | KEOL-500T MICRO SPRAY |

|---|---|---|---|

| Valve | Volumetric | Standard | Standard |

| Weight | NS. 650 g | NS. 225 g | NS. 246 g |

| Dosing volume | 0.5 to 6.0 ml / min | 0.1 to 0.8 ml / min | 0.1 to 0.8 ml / min |

| Volume flow rate | ±1 % | ±2,5 % | ±2,5 % |

| Control box | KEOL-K CONTROL SPRAY + KEOL-K 200 MONO | KEOL-VC 1000 | KEOL-VC 1000 |

| Technical datasheet |

Boitiers de contrôle KEOL-K 200 MONO, KEOL-K CONTROL SPRAY et KEOL-VC 1000

PIEZO VALVES WITHOUT CONTACT FOR ADHESIVE DISPENSING!

Contactless PIEZO valves allow precise metering of many types of fluids that differ in chemical composition as well as viscosity and may contain filler materials.

The contactless PIEZO valves allow in particular the non-contact depositing (jetting) of individual droplets on surfaces or components. PIEZO valves can dose drops up to a minimum size of 0.025 mg (depending on fluid and nozzle orifice).

Dispensing time can be set in 1.0 msec steps, allowing very precise dosing amounts to be configured.

PIEZO contactless valves are used for dosing various liquids in fully or partially automated industrial production facilities.

| Valves Piezo sans contact | Dimensions (mm) | Viscosity (m / step) | Control unit | Technical datasheet |

|---|---|---|---|---|

| KEOL JET MODULAR | 85 x 17 x 63 | Approximately 50 - 200,000 (tests needed) | 7 or 10 inch control screen; or standard housing | |

| KEOL JET BASIC | 86 x 15 x 40 | About 50 - 10,000 | Jet Basic Controller |

| Reference | KEOL K-200 Mono | KEOL-2K CONTROL | KEOL-K CONTROL SPRAY | KEOL-VC 1000 |

|---|---|---|---|---|

| Weight | Environ 980 g | Environ 1 300 g | Environ 1 650 g | Environ 3 kg |

| Dimensions (HxWxD) | 92,5 x 240 x 197 mm | 110 x 240 x 210 mm | 235 x 210 x 70 mm | 260 x 250 x 126 mm |

| Adapted valves | KEOL-K300, KEOL-K330, KEOL-450, KEOL-K600, KEOL-K700 | KEOL-2K330, KEOL-2K450 et KEOL-2K600 | KEOL-K spray | Standard |

| Technical datasheet |

How does an industrial adhesive dispensing valve work?

In the field of industrial assembly and bonding, it is essential to use equipment that can keep up with high speeds while offering precision work. The application of cyanoacrylate, anaerobic, epoxy, silicone, UV, acrylic or polyurethane adhesives requires the use of specific means to meet the challenges of production lines and the quality requirements of manufacturers.

The dispensing valves offered by KEOL are designed for adhesive dots, beads, filling/potting or spraying/spraying depending on the models used.

Thanks to the dedicated tanks upstream, these dispensing valves will allow to carry out high quality work, to dispense adhesives in a repeatable way even at high production rates, all this at low cost.

How do you choose the right dispensing valve for your production process?

There are different types of dispensing valves that can be chosen according to the requirements of your process, the nature of the materials to be assembled, the adhesives to be applied or the technical constraints encountered during the bonding process:

– Single component valves, ideal for dots, beads or filling, easy to clean and simple to use.

– Single component volumetric valves, which are recommended for use in a high repeatability production line with a reliability of +/-1% in deposited volume

– Two-component valves, which represent a light and functional piece of equipment that allows the application of two-component resins and adhesives in an optimum manner.

– Spray valves, which offer a uniform spray on the substrates in continuous or spot spraying mode.

– Non-contact or jet mode valves, also known as piezo valves, allow high production rates and optimal integration into automated systems. Without needles and therefore without contact, the adhesive is sprayed onto the workpiece.

The strength and high technology of KEOL dispensing valves means that they are virtually maintenance free, making assembly processes on production lines more flexible and productive.

Although our dispense valve models are relatively easy to program, KEOL provides advice and recommendations as well as a detailed programming process. We ensure that our products are of the highest quality and fit into production systems as easily as possible within the prerogatives of each industrial process.

Translated with www.DeepL.com/Translator (free version)