Treating a surface before gluing prepares the support and guarantees long-term hold and reliability of the assemblies.

Why treat a surface before gluing / coating?

Atmospheric Plasma is a treatment device for the preparation of surfaces in industrial production, it allows cleaning and surface activation on most materials such as plastic, metals, glass, semiconductor, FR4, etc. Treating a surface before adhesive prepares the support and guarantees long-term hold and reliability of the assemblies. With the Plasma device there is no need for chemical addition because the plasma activation process simply operates with compressed, dry and oil-free air. Due to the small size of the torch, the integration of the equipment can be easily adapted in the production or for automatic assembly process

| Plasma Equipment | Power (W/kHz) | Processing speed (m / sec.) | Band width (mm) | Power supply dimensions (mm) | Weight (kg) | Technical datasheet | |

|---|---|---|---|---|---|---|---|

| Torch | L 140 x ⌀ 40 | 0,5 | |||||

| Plasma Star | 300 / 30 | 200 à 400 | 8 à 14 | L 562 x H 211 x P 420 | 11,6 |

The KEOL-Plasma Star vacuum surface treatment system is more powerful than the atmospheric KEOL-Plasma Star system to improve the surface property and adhesion of the substrate. The KEOL-Plasma Star vacuum pre-treatment allows a part to be treated on all its surfaces, including large parts. The KEOL-Plasma Star vacuum system increases the surface property on parts including in areas not accessible with an atmospheric KEOL-Plasma Star treatment.

| Reference | Power (W/kHz) | Radio frequency | Loading /Unloading | Dimensions | Technical datasheet | |

|---|---|---|---|---|---|---|

| In-line vacuum plasma | Conveyor | Tailored | ||||

| Manual vacuum plasma | 40 | RF 13,56 MHz | Single door, double door, with drawers or revolving drum | Tailored |

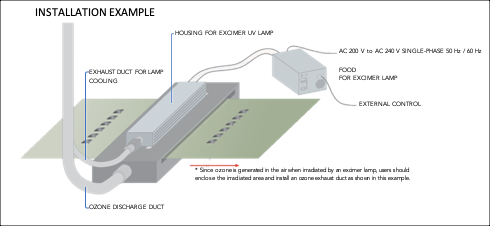

UV light with a wavelength of 172 nm in vacuum generates ozone and active oxygen in large quantities.

Bonds on the surface of the material are simultaneously broken by vacuum UV light which imparts hydrophilicity to the surface of the material as the chemical reaction forms functional groups on the pendant bonds to provide functionality. This increases the ability of the adhesive to form bonds with the substrates during its crosslinking.

| Equipment | Wavelength | Irradiation | Lamp life | Irradiation surface (mm) | Technical datasheet | ||

|---|---|---|---|---|---|---|---|

| Lamp holder | 10,3 kg | 400 x 38 mm | |||||

| UV Excimer lamp | 172 nm | *65 mW/cm² | 2 000 h | 220 g |

*Value calculated assuming that the irradiance is measured with a UV wattmeter placed in the immediate vicinity of the lamp.

The chemical primer allows manual treatment of plastic, metal, FR4 surfaces before bonding or coating by removing flux, glue, grease or silicone residues from bare and painted surfaces. Increases the surface energy of difficult plastics.

| Reference | Industry | Color | Chemical basis | Advantages | Technical datasheet | |

|---|---|---|---|---|---|---|

| KEOL-PRIMER 77 | X | Clear / amber | PRIMER ALL EP/PU/MMA | Ideal for the treatment of difficult plastics PP - PE - POM, etc. | ||

| KEOL-ACTIV 3109 | X | Colorless | ACTIVATOR | Manual treatment, eliminates residues | ||

| KEOL-PRIMER 3793 | X | Colorless | PRIMER | Improves surface energy before bonding |