From solutions tailor-made and adapted, sector through sector. Industrial bonding applications for composites use high strength epoxy or polyurethane structural adhesives. In the medical sector, the adhesives and solutions offered improve your productivity and the quality of your adhesives assemblies. In the electronics sector, UV coating solutions on PCBs with selective spray application protect components from shock humidity. In the cosmetics / luxury sector, the finishing adhesive of accessories on perfume bottles is carried out with UV glues, associated with precise application means as well as high intensity LED / UV lamps.

The industrial sector has a very wide range of industrial adhesives for assembly by bonding such as epoxy adhesives, hybrid adhesives, acrylic adhesives, methacrylate adhesives, silicone adhesives, cyanoacrylate adhesives, etc.

Bonding has the additional advantage of allowing the production of extremely strong structural assemblies and replaces conventional assembly methods such as riveting, welding and brazing.

The anti-rust warranty on recent automobiles is due to the introduction of bonding in the assembly of the bodywork.

Bonding, a unique assembly method!

The adhesive assembly of medical devices represents a particular skill. Adhesives suitable for the medical sector must be certified in accordance with biocompatibility standards such as USP class VI and ISO 10993. The applications characterized in the medical field range from the sticking of needles or cannula which requires excellent resistance of the needles to the test tearing, but also for bonding and sealing connectors and catheters.

Because the adhesive must not come into contact with liquids at the adhesive joints, the most suitable method for depositing the glue will be by capillary action, which is particularly well suited for medical devices.

The adhesives generally used in this field are UV acrylates, cyanoacrylates, and single and two-component epoxy adhesives.

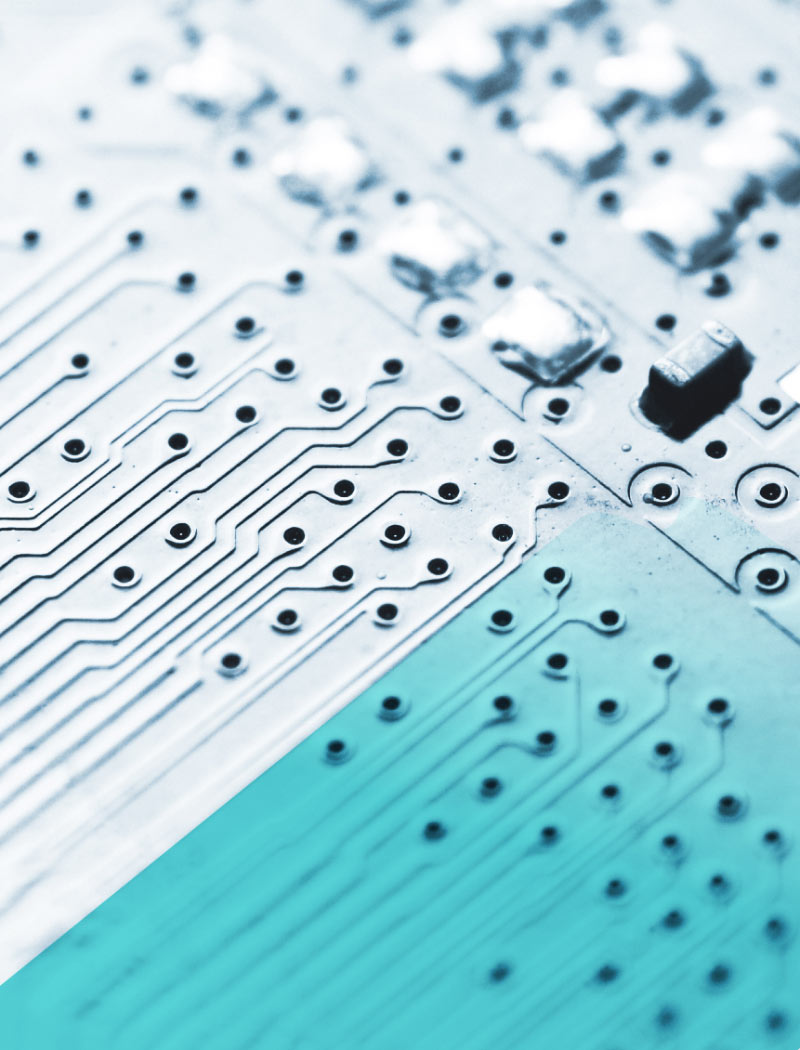

Adhesive and varnishing in the field of electronics and electromechanics ensures a tight assembly and guarantees high-performance protection between the different components used. In fact, humidity, aggressive and abrasive environments, UV radiation, inviolability, mechanical stresses and vibrations require suitable protection.

The electronic coating reinforces the resistance of components to shocks and vibrations and promotes their moisture tightness.

Bonding in the field of cosmetics and luxury packaging, is used for assemblies on glass, transparent or not transparent plastics, as well as for bonding hoops, caps and decorative pieces in metal, plastics or metallized plastics. Bonding in cosmetics and luxury packaging requires high-quality aesthetics. The bonding provides transparency to the assembly and is non-yellowing.

The industrial sector has a very wide range of industrial adhesives for assembly by bonding such as epoxy adhesives, hybrid adhesives, acrylic adhesives, methacrylate adhesives, silicone adhesives, cyanoacrylate adhesives, etc.

Bonding has the additional advantage of allowing the production of extremely strong structural assemblies and replaces conventional assembly methods such as riveting, welding and brazing.

The anti-rust warranty on recent automobiles is due to the introduction of bonding in the assembly of the bodywork.

Bonding, a unique assembly method!

The adhesive assembly of medical devices represents a particular skill. Adhesives suitable for the medical sector must be certified in accordance with biocompatibility standards such as USP class VI and ISO 10993. The applications characterized in the medical field range from the sticking of needles or cannula which requires excellent resistance of the needles to the test tearing, but also for bonding and sealing connectors and catheters.

Because the adhesive must not come into contact with liquids at the adhesive joints, the most suitable method for depositing the glue will be by capillary action, which is particularly well suited for medical devices.

The adhesives generally used in this field are UV acrylates, cyanoacrylates, and single and two-component epoxy adhesives.

Adhesive and varnishing in the field of electronics and electromechanics ensures a tight assembly and guarantees high-performance protection between the different components used. In fact, humidity, aggressive and abrasive environments, UV radiation, inviolability, mechanical stresses and vibrations require suitable protection.

The electronic coating reinforces the resistance of components to shocks and vibrations and promotes their moisture tightness.

Bonding in the field of cosmetics and luxury packaging, is used for assemblies on glass, transparent or not transparent plastics, as well as for bonding hoops, caps and decorative pieces in metal, plastics or metallized plastics. Bonding in cosmetics and luxury packaging requires high-quality aesthetics. The bonding provides transparency to the assembly and is non-yellowing.